We offer more than 75 crushed stone products available in a variety of colors, sizes, and gradations.

Concrete Parking Lots

Parking Lot Repair: Concrete vs. Asphalt

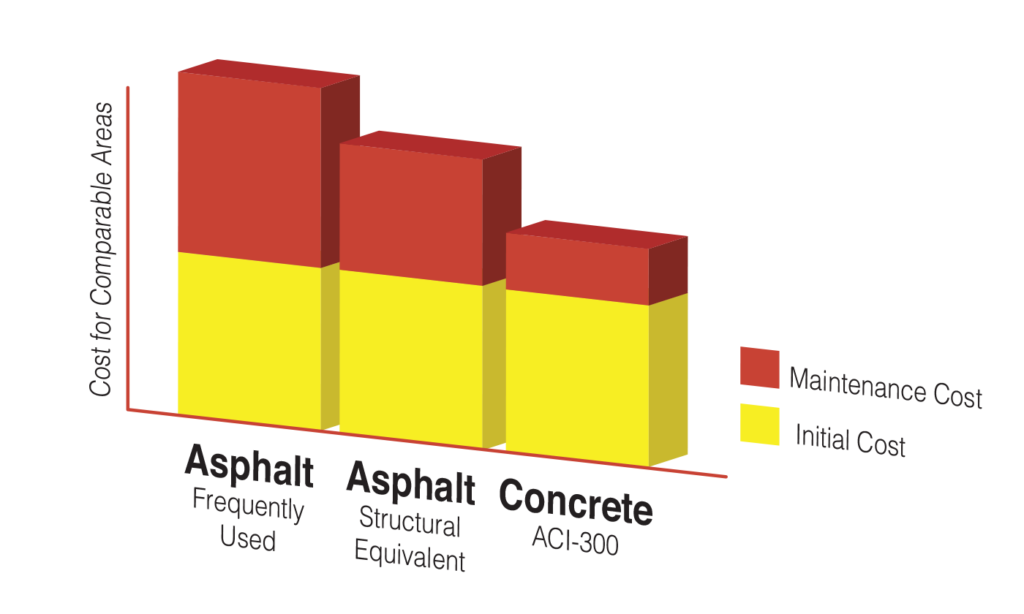

When it comes to paving a parking lot as well as parking lot repair, asphalt has long been thought of as a better choice over concrete for parking lots because it is cheaper, however, this is no longer the case. Concrete has many advantages over asphalt—economical, environmental, aesthetic, and safety benefits make concrete a great choice for any parking lot.

Economical Benefits

With the price of oil skyrocketing, laying a concrete parking lot is now comparable in cost to laying asphalt. Concrete is more durable and has a longer lifecycle. It requires less maintenance and upkeep than asphalt, making concrete a less expensive option with a long-term higher value.

Concrete is composed of local American-mined and -manufactured materials (unlike oil and tar that make up asphalt), so we can keep our money here and create more American jobs.

Recent advancements in 3D laser screeds make placing large, level concrete parking lots easy and can reduce crew size and increase production rates. A curb can also be placed at the same time as the parking lot, eliminating the need for additional subcontractors and increasing efficiency.

Environmental Benefits

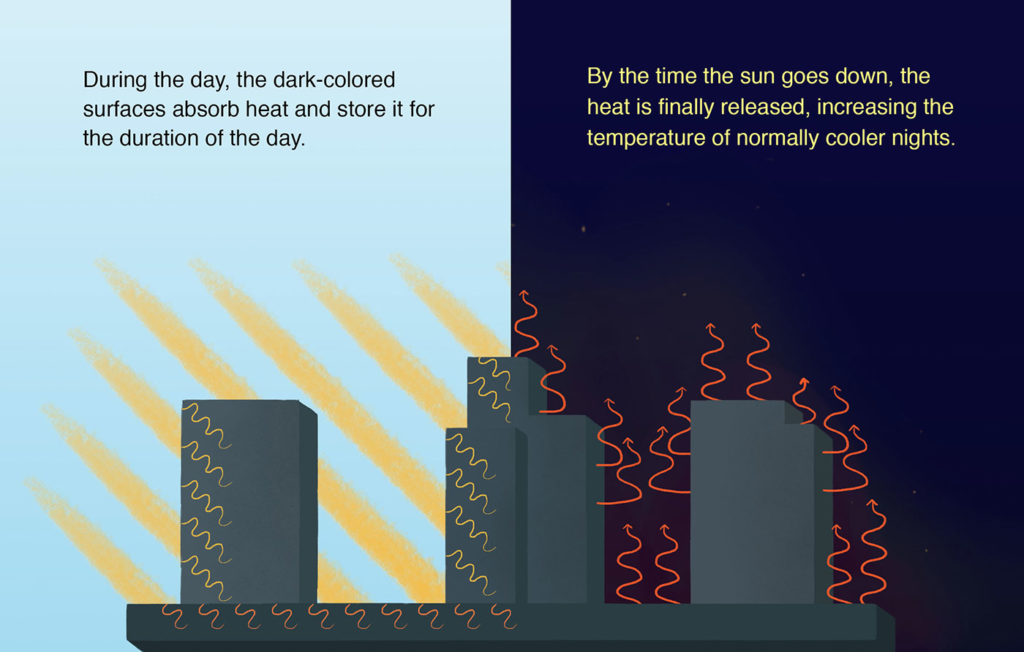

With its lighter color and higher reflectivity, concrete lowers the urban heat island effect. Concrete absorbs less of the sun’s energy than black asphalt, requiring less electricity to cool surrounding buildings.

Concrete also reduces the number of lights necessary to brighten the white concrete lots, reducing energy costs by up to 30 percent.

Unlike asphalt, concrete is composed of local American-made materials. These materials need to travel far shorter distances, cutting down on the carbon footprint of raw materials. Concrete is also 100 percent recyclable and eliminates the use of oil and tar used for asphalt lots. Oil and tar pollute nearby bodies of water and the surrounding landscape.

A major advantage of concrete over asphalt is that it can provide upwards of 74 LEED Certification points for parking lots and up to 110 points for other structural categories. Entry-level LEED Certification is 40-49 points, Silver level is 50-59 points, Gold level is 60-79 points and Platinum level is 80+ points.

Green Concrete Uses Recycled Materials

Fly ash is a byproduct of burning coal and generally takes up space at power plants or in landfills, however it can also be used as a partial replacement for Portland cement. Fly ash actually makes concrete denser, stronger, and more durable long term. It also helps contractors earn LEED certification.

Aesthetic and Safety Benefits

Concrete can be tailored to personal design tastes with its wide variety of colors and patterns—asphalt is only available in black. Properties are instantly made more attractive by concrete’s curb appeal and cracking resistance. Lighter color and higher light reflectivity means that concrete parking lots are naturally brighter at night as compared with asphalt lots, making them much more safe for pedestrians and drivers.

Solutions for Existing Asphalt Parking Lots: Parking Lot Repair

An asphalt parking lot full of potholes is both an eyesore and a safety hazard. You can transform your deteriorated asphalt surface into an attractive, functional parking area by covering it with a concrete overlay called whitetopping. Let Silvi Materials aid you in creating a safer and more energy efficient parking lot through our parking lot repair.